3D printers to be used in fuel manufacture

Ultra Safe Nuclear Corporation (USNC) has adopted two 3D printers from additive manufacturing technology company Desktop Metal to form nuclear-grade silicon carbide for use in its innovative Fully Ceramic Microencapsulated (FCM) nuclear fuel.

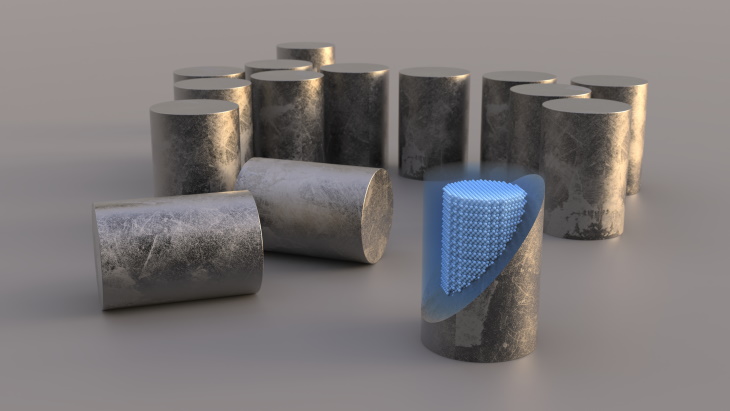

FCM fuel pellets contain TRISO praticles - shown in blue - encased in silicon carbide (Image: USNC)

The printers are from Desktop Metal's X-Series line of binder jetting systems. USNC plans to adopt two more machines later this year, Desktop Metal said.

USNC's FCM fuel - which the company intends to use in its Micro Modular Reactor (MMR) - incorporates TRISO (uranium oxycarbide tristructural isotropic) fuel particles encased in a silicon carbide matrix. According to a case study by Desktop Metal, application of binder jet 3D printers facilitates a key step in manufacturing the fuel.

Binder jet 3D printing inkjets a binder into a bed of powder particles such as metal, sand, or ceramic to create a solid part, one thin layer at a time, without the need for the hard tooling used in traditional methods of processing technical ceramics. Furthermore, unlike 3D printing processes which rely on high temperatures during the deposition process to melt metal particles to connect them, the whole process is carried out at low temperatures: an important consideration for silicon carbide, which has a high melting point.

Printing directly from digital design files without the need for tooling allows designs to be iterated quickly, and enables the creation of unique shapes not otherwise manufacturable.

"Binder jetting is a low-cost, high-yield, reliable process for our complex serial production," said Kurt Terrani, executive vice president of USNC's Core Division. "The advanced material capability of the X-Series machines is fundamental to our innovative approach to fuel design."

A small-format X-Series printer, InnoventX, is already installed at USNC's facility in Salt Lake City, Utah, and the nuclear fuel matrix has been developed to be scaled up on the larger X25Pro and X160Pro systems.

Earlier this year, UNSC licensed a 3D-printing process for manufacturing refractory ceramic carbides using binder jet printing combined with chemical vapour infiltration from Oak Ridge National Laboratory. It has also announced that it plans to begin operations later this year at a pilot manufacturing facility in Oak Ridge, Tennessee, where feedstock uranium powder will be processed into TRISO fuel particles.

USNC's MMR is a 15 MW thermal, 5 MW electrical high-temperature gas-cooled reactor which is currently undergoing licensing in Canada and the USA. Global First Power plans to build and operate an MMR unit at Chalk River Laboratories in Canada by 2026.

Researched and written by World Nuclear News

- China Institute of Atomic Energy

- Nuclear Power Institute of China

- Southwestern Institute of Physics

- China Nuclear Power Operation Technology Corporation, Ltd.

- China Nuclear Power Engineering Co., Ltd.

- China Institute for Radiation Protection

- Beijing Research Institute of Uranium Geology (BRIUG)

- China Institute of Nuclear Industry Strategy (CINIS)

- China Nuclear Mining Science and Technology Corporation