Tweaks to FLEX design sees boost in power output

MoltexFLEX says a reevaluation of certain aspects of its FLEX molten salt reactor design has "yielded a more robust scientific and engineering foundation" for the reactor. A refinement of the reactor design has delivered a 50% boost in power output, while maintaining previous targets for overnight capital cost and cost per MWh.

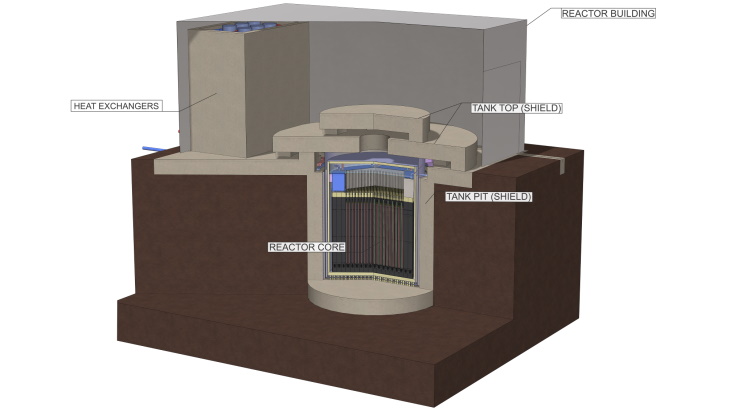

A cutaway of the FLEX reactor design (Image: MoltexFLEX)

Warrington, UK-headquartered MoltexFLEX - a subsidiary of Moltex Energy Limited - is developing the FLEX reactor – the thermal neutron (moderated) version of Moltex Energy's stable salt reactor technology. The reactor is small and modular, allowing components to be factory-produced and readily transportable, reducing on-site work, increasing speed of construction, and minimising overall costs. It is passively safe, so does not require engineered, redundant, active safety systems. The FLEX reactor has no moving parts and is fuelled for 20 years at a time, meaning that there is very little operator input and very low ongoing costs. Each reactor was initially expected to deliver 40 MW of thermal energy at 700°C. According to MoltexFLEX, the cost of electricity generated by the FLEX reactor was likely to be GBP40 (USD50) per MWh. MoltexFLEX plans to have its first reactor operational by 2029.

Following a reevaluation of the design, MoltexFLEX says FLEX's power output has increased from 40 MWth/16 MWe as originally envisaged to 60 MWth/24 MWe, made possible by optimisation of the core design and the fuel pin material.

The refuelling schedule has also been adjusted to account for the fact that the FLEX reactor will now use 5% low-enriched uranium (LEU) instead of 6% LEU. MoltexFLEX said this change "facilitates global deployment of the FLEX reactor by leveraging established security and non-proliferation measures and the existing fuel supply chain".

The refinement of the design has also maintained the predicted overnight capital cost of an nth-of-a-kind reactor at approximately GBP2000/kW, and the levelised cost of electricity of a baseload electricity generating plant at less than GBP30/MWh.

MoltexFLEX said that while the underlying technology remains essentially unchanged, these design evolutions represent significant improvements. "The work provides more certainty about the company's ability to deliver on its cost targets, reinforces the underpinning science, and sets MoltexFLEX on the road toward delivering its prototype FLEX reactor around the turn of the decade," it said.

"We have firmly established the core aspects of the FLEX concept as we ramp up engineering design," said MoltexFLEX Head of Engineering Chris Hankinson. "More work will be undertaken over the coming months to further refine and finally freeze the design, and this will then be taken forward to create our first-of-a-kind reactor."

"The science and engineering of the FLEX reactor has moved on apace," said MoltexFLEX CEO David Landon. "The work we have completed further boosts our confidence in the design and economics of the FLEX reactor, and our ability to deliver a first reactor ready for global roll-out through the 2030s."

In May 2021, the Canadian Nuclear Safety Commission completed the first phase of the pre-licensing vendor design review for Moltex Energy's 300 MWe Stable Salt Reactor - Wasteburner (SSR-W 300) small modular reactor. The SSR-W is a molten salt reactor that uses nuclear waste as fuel. The company aims to deploy its first such reactor at the Point Lepreau site in New Brunswick by the early 2030s.

Researched and written by World Nuclear News

- China Institute of Atomic Energy

- Nuclear Power Institute of China

- Southwestern Institute of Physics

- China Nuclear Power Operation Technology Corporation, Ltd.

- China Nuclear Power Engineering Co., Ltd.

- China Institute for Radiation Protection

- Beijing Research Institute of Uranium Geology (BRIUG)

- China Institute of Nuclear Industry Strategy (CINIS)

- China Nuclear Mining Science and Technology Corporation