The Bochvar Institute has developed a fuel rod design based on nitride uranium-plutonium fuel (MNUP-fuel) for the BREST-OD-300 fast neutron reactor. At the same time, Rosatom’s nuclear fuel division is developing second-generation fuel rods for the BREST-OD-300 with a higher burnout level, which will be used when MNUP fabrication will shift to the re-fabrication stage. This means that irradiated fuel of the first load after irradiation and reprocessing will be used for fresh fuel fabrication. Meanwhile, Rosatom has launched a tender to study the pyrochemical processing of used nuclear fuel from fast neutron reactors.

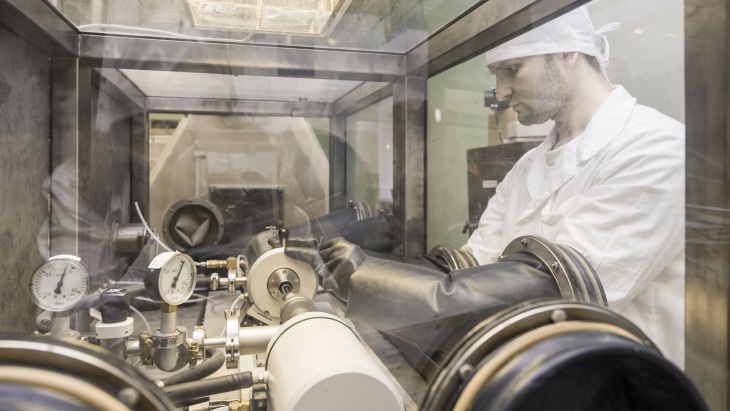

Rosatom's Breakthrough project aims to demonstrate closing the nuclear fuel cycle (Image: TVEL)

All of these activities are part of Rosatom's Proryv (Breakthrough) project, the ultimate aim of which is to demonstrate closing the nuclear fuel cycle. This project also includes construction of a Pilot Demonstration Energy Complex (PDEC) at the site of Siberian Chemical Combine (SCC), which is in Seversk, in the Tomsk region of Russia.

The Bochvar Institute is a research facility of Rosatom's nuclear fuel manufacturing subsidiary TVEL, which said today that the MNUP-fuel project will be applied to the commercial manufacturing of nitride fuel to be launched as part of the PDEC. SCC is another TVEL subsidiary.

"Pilot fuel assemblies with nitride fuel have been irradiated in the BN-600 reactor at the Beloyarsk nuclear power plant since 2014," Mikhail Skupov, deputy director general of the Bochvar Institute, said in the TVEL statement. "Though the sufficient validated fuel burnout for the BREST initial load is 6%, in the course of the testing we have already achieved the 9% level. These results give us grounds for the fuel rod endurance tests with 9-10% burnout."

Alexander Ugryumov, vice president for research, development and quality at TVEL, added that the research results related to nitride fuel for the BREST reactor will significantly accelerate fuel development for the nitride core version of the next generation BN-1200M fast reactor. "In 2022, experimental fuel assemblies with fuel rods of the BN-1200M type are scheduled to be loaded in the BN-600 for endurance tests," he said.

SCC is working on the construction of the MNUP-fuel fabrication/re-fabrication module as part of the PDEC. On 10 February, Russian regulator Rostechnadzor issued a licence for the construction of BREST-OD-300, which Rosatom describes as the world's first power unit with a lead-cooled fast neutron reactor.

Separately, Rosatom has launched a tender to study the pyrochemical processing of used nuclear fuel from fast neutron reactors as part of the Proryv project. The tender notice states that Rosatom is offering a RUB301 million (USD4.7 million) contract for this work. Bids must be submitted by 17 March.

The work will involve experimentally testing the main processes of the pyrochemical processing of used nuclear fuel. Several technologies for processing waste from experimental nuclear fuel developed as part of the Proryv project - the MNUP-fuel - are to be used.

Researched and written by World Nuclear News