The manufacture of the first of five vacuum vessel sectors under the responsibility of Fusion for Energy (F4E) - the ITER Organisation's European domestic agency - has now been completed in Italy. The component is set to be delivered to the construction site of the tokamak fusion device in Cadarache, France.

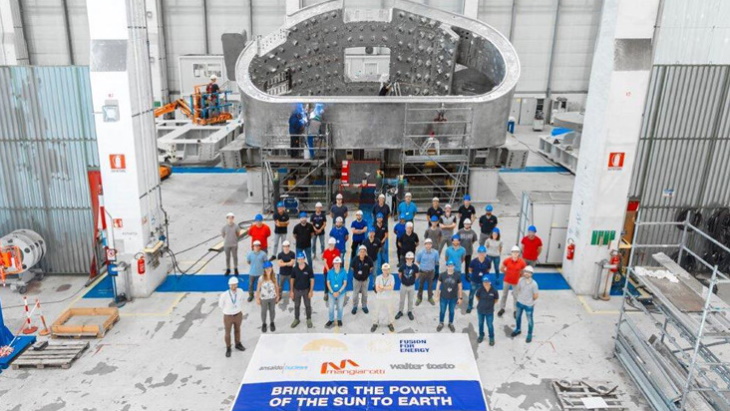

The completed ITER vacuum vessel sector (Image: F4E)

The International Thermonuclear Experimental Reactor's (ITER) plasma chamber, or vacuum vessel, houses the fusion reactions and acts as a first safety containment barrier. With an interior volume of 1400 cubic metres, it will be formed from nine wedge-shaped steel sectors that measure more than 14 metres in height and weigh 440 tonnes. The ITER vacuum vessel, once assembled, will have an outer diameter of 19.4 metres, a height of 11.4 metres, and weigh approximately 5200 tonnes. With the subsequent installation of in-vessel components such as the blanket and the divertor, the vacuum vessel will weigh 8500 tonnes.

The fabrication of the vacuum vessel sectors is shared between Europe (5 sectors) and Korea (4 sectors). Vacuum vessel sector No 6, at the centre of the assembly, and associated thermal shielding has already been manufactured and delivered by the Korean Domestic Agency.

Each sector counts roughly 150 km of welding beads. In all manufacturing sites, large teams of technicians, metrology experts, engineers and quality assurance officers continuously inspected the production to mitigate risks. More than 20,000 hours of machining and at least 100,000 hours of welding were required to produce Europe's first sector. Two of its segments (1 and 4) were manufactured by Westinghouse in Monfalcone, while the other two (2 and 3) were produced by Walter Tosto in Chieti.

The first sector, No 5, being supplied by Europe has now been assembled at the Westinghouse/Mangiarotti facility in Monfalcone, Italy.

In a ceremony held in Monfalcone, senior representatives from industry and policymakers gathered to celebrate the technical milestone for the ITER project. The sector's fabrication builds on ten years of work directly involving more than 150 professionals, and at least 15 companies across Europe with their respective workforces.

"Europe's first sector results from the partnership between F4E, the consortium of Ansaldo Nucleare, Westinghouse, Walter Tosto and ITER Organization," said F4E Director Marc Lachaise. "Our commitment to deliver, the teamwork and innovative thinking have been the driving forces of this impressive achievement."

The sector is expected to depart from Italy before the end of September and will travel by sea to Fos-sur-Mer, the industrial port of Marseille, France. It will then be loaded on to a massive trailer to be driven to ITER site. Europe's remaining four sectors are in production and will be delivered in the next two years.

ITER is a major international project to build a tokamak fusion device in Cadarache, France, designed to prove the feasibility of fusion as a large-scale and carbon-free source of energy. The goal of ITER is to operate at 500 MW (for at least 400 seconds continuously) with 50 MW of plasma heating power input. It appears that an additional 300 MWe of electricity input may be required in operation. No electricity will be generated at ITER.

Thirty-five nations are collaborating to build ITER - the European Union is contributing almost half of the cost of its construction, while the other six members (China, India, Japan, South Korea, Russia and the USA) are contributing equally to the rest. Construction began in 2010 and the original 2018 first plasma target date was put back to 2025 by the ITER council in 2016. However, in June this year, a revamped project plan was announced which aims for "a scientifically and technically robust initial phase of operations, including deuterium-deuterium fusion operation in 2035 followed by full magnetic energy and plasma current operation".