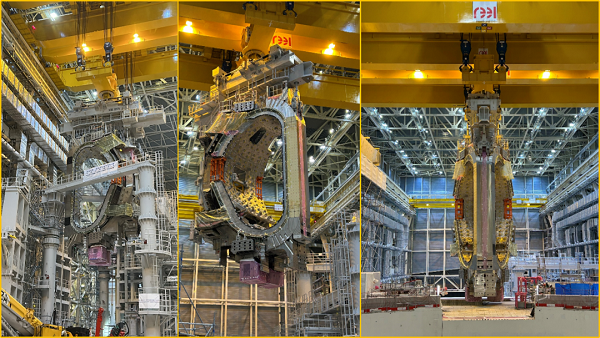

On April 10, the first vacuum vessel module (Module 7) of the ITER was installed, becoming the first core sector module of the Sector Modules Sub-Assembly (SMSA) to be placed in the Tokamak pit.

ITER Director-General Pietro Barabaschi sent a letter to all participants, including the consortium of China Nuclear Power Engineering (CNPE) Co. Ltd., a subsidiary of China National Nuclear Corporation (CNNC). He praised this achievement as a reflection of the outstanding expertise, courage, and dedication of everyone involved. As the project's contractor, the consortium brought together the capabilities of all parties to complete the operation, marking a new milestone in its contribution to major international big science projects and the promotion of global fusion cooperation.

The SMSA of the ITER involves the precise integration of the Tokamak's three most critical components: the vacuum chamber, toroidal field coil, and vacuum vessel thermal shield. This is a complex and systematic engineering task that requires meticulous technical development, careful construction organization, and highly skilled workers. It spans multiple specialized fields, including assembly, heavy lifting, welding, and precision machining. During the bidding phase, a joint team composed of eight companies from China, France, and Italy demonstrated its exceptional expertise and deep understanding of the project, successfully securing the installation contract and laying a solid foundation for the project's commencement.

The successful placement of the ITER's Module 7 was completed three weeks ahead of schedule, demonstrating the immense potential of international cooperation. The lift, weighing 1,368 tons in total, raised exceptionally high demands on precision control, coordinated execution, and safety assurance. It also broke multiple records for component lifting in the ITER project. Engineers and technicians from China, France, and Italy worked closely together, independently developing and implementing a detailed lifting plan. They overcame several key technical challenges, including lifting posture control, millimeter-level alignment, and high-strength structural synchronization, to ensure that the Module 7 was safely, precisely, and stably positioned. Significant breakthroughs were also achieved in the key processes such as pipeline welding, instrument installation and precision machining with the joint efforts of the consortium, ensuring quality while optimizing the project timeline.

The consortium will take this opportunity to deepen communication and collaboration with international counterparts, and expand the scope of cooperation. It will actively seek partnerships with outstanding companies worldwide to jointly develop new ITER contracts and drive further progress in the project.