Work starts on Finnish fuel encapsulation plant

Finnish waste management company Posiva today announced the start of construction of the used fuel encapsulation plant at the Olkiluoto site in western Finland. Installation of the necessary systems within the underground disposal chambers is also set to begin soon.

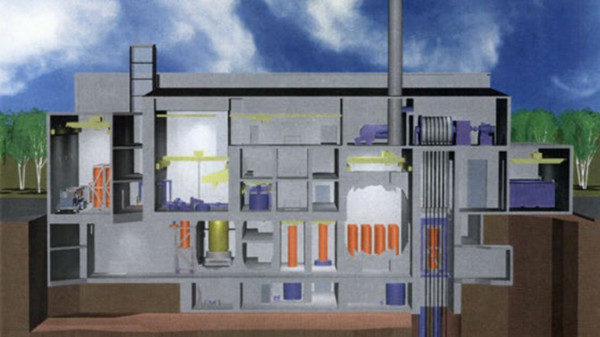

A cross section of the planned encapsulation plant (Image: Posiva)

The site for Posiva's repository at Eurajoki, near the Olkiluoto nuclear power plant, was selected in 2000. The Finnish parliament approved the decision-in-principle on the repository project the following year. Posiva, jointly owned by Finnish nuclear utilities Fortum and Teollisuuden Voima Oyj, submitted its construction licence application to the Ministry of Employment and the Economy in December 2013. Posiva studied the rock at Olkiluoto and prepared its licence application using results from the Onkalo underground laboratory, which would be expanded to form the basis of the repository. The government granted a construction licence for the project in November 2015 and construction work on the repository started a year later. Posiva is still required to obtain a separate operating licence for the facility.

Posiva's plan is for used fuel to be packed inside copper-steel canisters at an above-ground encapsulation plant, from where they will be transferred into the underground tunnels of the repository, located at a depth of 400-450 meters, and further into deposition holes lined with a bentonite buffer. Operation of the repository is expected to begin in 2023.

The cost estimate of this large-scale construction project totals about EUR500 million (USD570 million), the company said.

Once commissioned, used fuel will be delivered in transportation casks to the receiving area of the encapsulating plant. This receiving area is also the place where the empty final disposal canisters are delivered. In the encapsulation plant, both the transportation cask and the final disposal canister will then be docked tightly inside the fuel handling cell, where the fuel is transferred from the transportation cask first to the drying station and then to the final disposal canister. When all fuel assemblies have been transferred to the canister, it will be filled with argon gas and then tightly closed with an inner steel cover.

From the handling cell, the filled canister will then be transferred to a welding station. Here the canister lid will be sealed with electron beam welding, which guarantees a tight and strong seam. Next, the tightness of the weld will be inspected at an inspection station using non-destructive testing methods, such as x-ray and ultrasonic testing.

Posiva said the encapsulation plant has been designed in such a way that no hazardous amounts of radioactive substances will be released into the environment, even if a disturbance occurs during the fuel encapsulation process. Canisters that have passed the inspection will then be transferred either by lift or by the access tunnel with a special-purpose vehicle to the final disposal facility.

"This very significant project we are about to launch covers the encapsulation plant as a whole, the systems which are needed to begin final disposal, the operating licence process, and preparations for the supply chains required for the production stage of the facility," said Posiva President Janne Mokka. "The project's main focus requires experts who have worked for four decades on developing the safe final disposal concept, as well as professionals of project management and various partners. We expect to award contracts for the most significant works in the near future."

Last month, Posiva announced that the full-scale in situ system test at the Onkalo underground characterisation facility had proceeded to the concreting phase in the construction of the end plug for the deposition tunnel. The test ensures the functionality of storing nuclear fuel assemblies packed in the copper-steel canisters in tunnels drilled into rocks, as well as backfilling the tunnels with bentonite clay and sealing them with reinforced concrete plugs.

Mokka noted, "In Finland, full lifecycle management is a precondition for the production of climate-friendly nuclear electricity. Posiva will execute the final disposal of the spent fuel of its owners' Olkiluoto and Loviisa nuclear power plants responsibly."

Sweden is planning a similar used fuel encapsulation and disposal facility using the same storage method. Under its current timetable, national radioactive waste management company Svensk Kärnbränslehantering AB plans to start construction of the used fuel repository and the encapsulation plant sometime early in the 2020s and they will take about 10 years to complete.

- China Institute of Atomic Energy

- Nuclear Power Institute of China

- Southwestern Institute of Physics

- China Nuclear Power Operation Technology Corporation, Ltd.

- China Nuclear Power Engineering Co., Ltd.

- China Institute for Radiation Protection

- Beijing Research Institute of Uranium Geology (BRIUG)

- China Institute of Nuclear Industry Strategy (CINIS)

- China Nuclear Mining Science and Technology Corporation